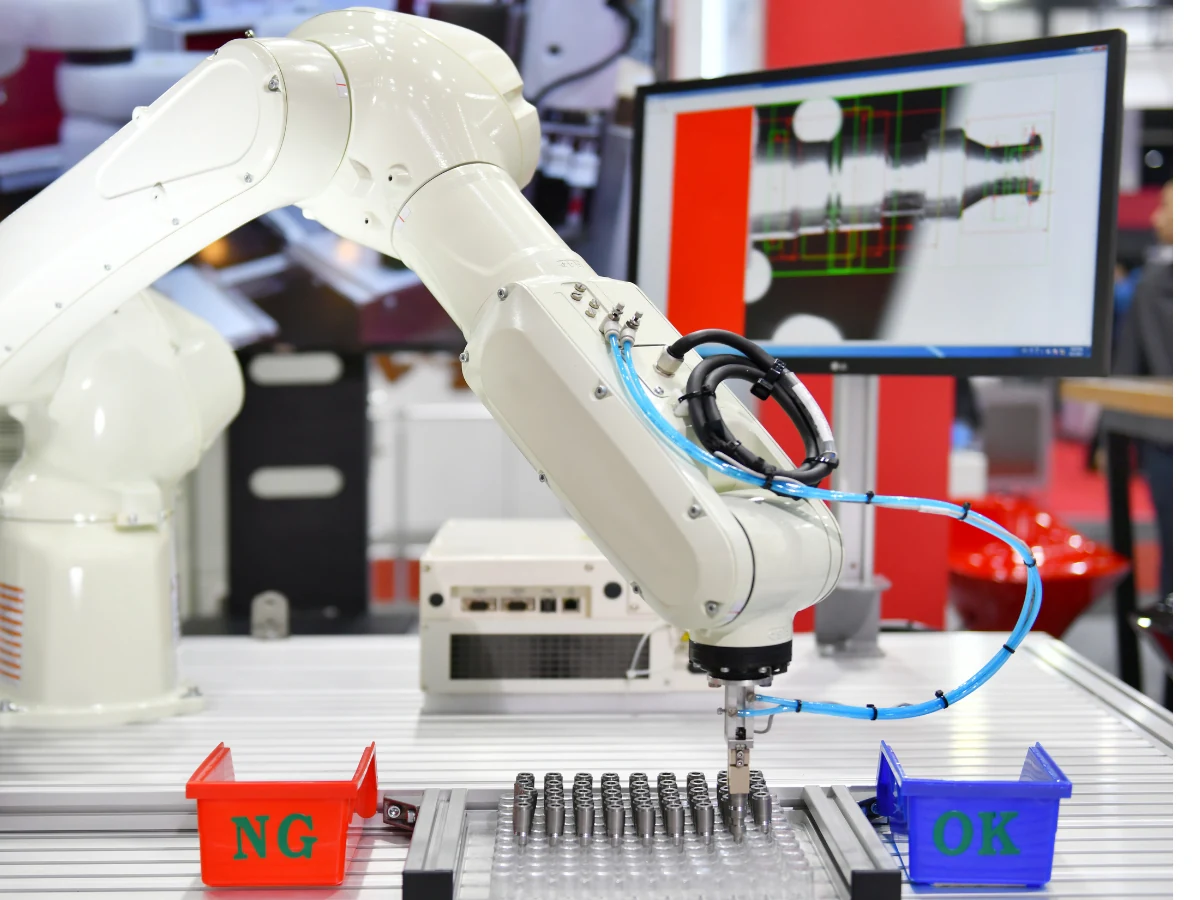

Artificial vision systems are revolutionizing quality control in production lines. These technologies enable the automatic identification of defects, anomalies, or imperfections with accuracy surpassing the human eye, helping to improve product quality and company competitiveness.

Machine vision uses high-resolution cameras, image processing software, and artificial intelligence algorithms to analyze every single piece passing through the line. This type of inspection can be integrated at different stages of production: at the input to check raw materials, during processing to monitor critical phases, or at the output to validate the finished product.

One of the main advantages is consistency in results. Unlike human inspection, which is subject to fatigue and variability, vision systems operate with the same level of accuracy 24/7, reducing the margin of error.

These solutions are also essential for traceability. Every anomaly is recorded, linked to a product code, and made available for subsequent analysis. This allows for more precise management of non-conformities and continuous process improvement.

Moreover, artificial vision systems increase productivity. Automatic inspections are faster and enable handling large volumes without slowdowns. This results in greater efficiency and reduced time-to-market.

Finally, using these technologies contributes to workplace safety by reducing the need for manual interventions in critical or repetitive phases.